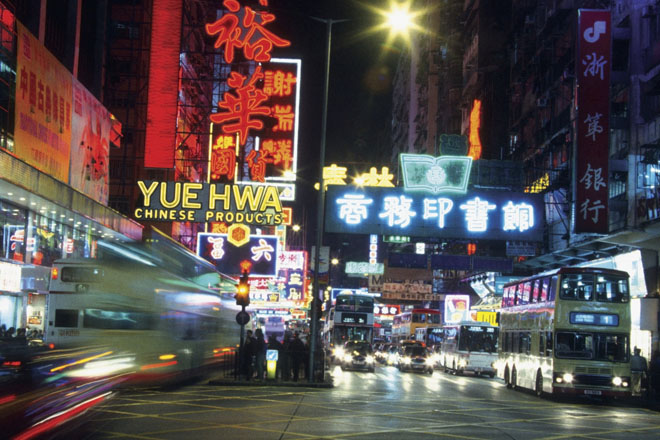

Rising in the East Part 1: Structure and Process

East Asian companies have different business cultures to those in Europe and the US, and so successful has their approach been that Western companies have looked east for lessons in their own expansion.

A notable example is US aircraft manufacturer Boeing, which has studied the manufacturing techniques and emphasis on quality developed by the Japanese automotive sector. Boeing even adopted the Japanese word for consistent improvement, kaizen, to describe the “employee-driven philosophy” it calls ‘Lean’.

In the past ten years, the international expansion of Asian companies has accelerated. The continent’s businesses have invested more than US$2.9 trillion in regional and global expansion since 2003, according to Accenture’s Growth Journeys report. The largest proportion of this total, US$58 billion, was invested in Western Europe, but from North America to the Middle East, no global territory has been ignored by Asian companies looking to grow.

The most recent flood of investment is part of a long history of global expansion, particularly among East Asian companies. Brands such as Nissan, Canon and Samsung have been household names in the West for decades. All three companies were founded in the 1930s; Nissan and Canon started their programmes of global expansion in the 1950s, and Samsung followed two decades later. There’s little doubt today that in scale, innovation and clout, global businesses that have emerged from this region rival any that were born in the West. So what is their secret, and is it any different to the companies whose territories they now inhabit?

“Kaizen is now a familiar word in the Western business lexicon,” says Simon Sproule, who recently left his post as Corporate Vice President of Global Marketing Communications at Nissan. Even US-born concepts have been earmarked for Eastern makeovers. “A lot of six sigma [a quality management approach developed by the American firm GE] disciplines and principles come from things like kaizen and the manufacturing quality technologies and processes that were advanced by the Japanese,” says Sproule.

During the export-led expansion of Japanese firms throughout the second half of the 20th century, the Japanese approach to manufacturing often travelled with the goods. “The companies started manufacturing things outside of Japan, and they took their processes with them, which is how they have maintained a ‘Japanese’ manufactured level of quality, but manufactured outside the country,” says Sproule.

Japanese organisational culture is also defined by procedure, which helped transport organisational behaviours and hierarchies completely – making them easy to reproduce. “This is what Japan excels at – structure and process,” says Sproule.

Engage with fellow HR professionals across the globe and stay up to date with the latest HR news, by joining our LinkedIn group.